PPM offer support and highly qualified services in the following areas:

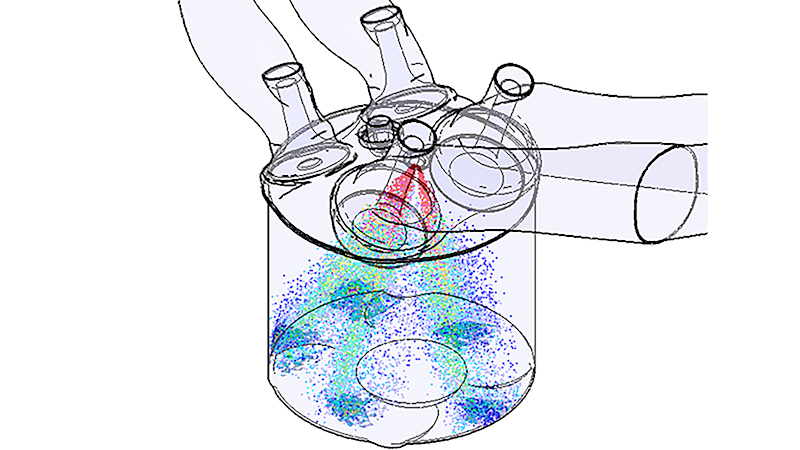

- CFD and 0D/1D modelling of internal combustion engines

- Development of tailored software and methodologies to support the entire CFD modelling process (from meshing to automatised post-processing)

- Robust methodologies for the calibration of semi-fundamental models

- Spray modelling and spray pattern/targeting optimisation

- Development of tailor-made surrogate fuel blend models

- Combustion modelling including chemical kinetics and soot formation

- Soot mechanisms and interactions in modern high injection pressure Gasoline Direct Injection engines

- Advanced mesh morphing approaches for the simulation of gas and particle dispersion in large urban contexts

- Conjugate heat transfer simulations

- Engine testing, including emission analysis (gas analysers and FTIR) and engine-out Particulate Matter characterisation (DMS-500 by Cambustion)

- Testing of fuels and impact on PM/PN emissions

- Ammonia-hydrogen combustion