Winner, Engineering Excellence Award, KTP Best of the Best Awards

Finalist, Best Partnership Award, KTP Best of the Best Awards

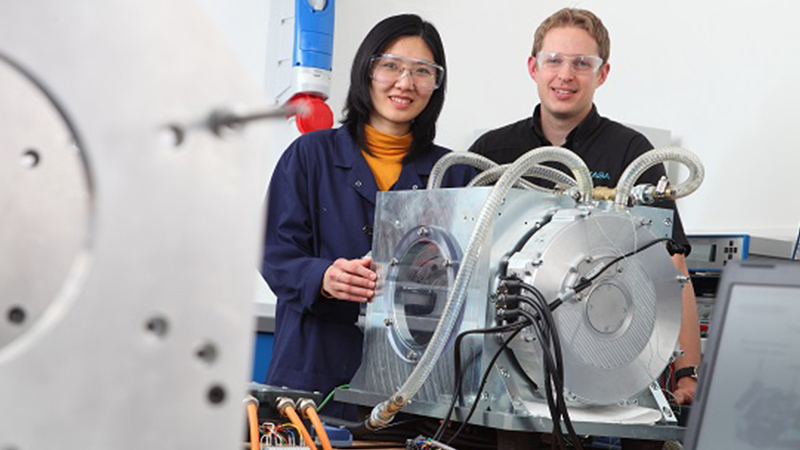

Game-changing, ground-breaking, best-in-class: the electric motors from Oxfordshire company YASA Motors make news not just in motorsport now, but across sectors ranging from industrial to marine and aerospace. The remarkable designs were produced with expertise from Oxford Brookes University and radically shortened production times, increased performance, cut costs, and improved reliability, preparing the company for mass production.

Read more about Yasa Motors

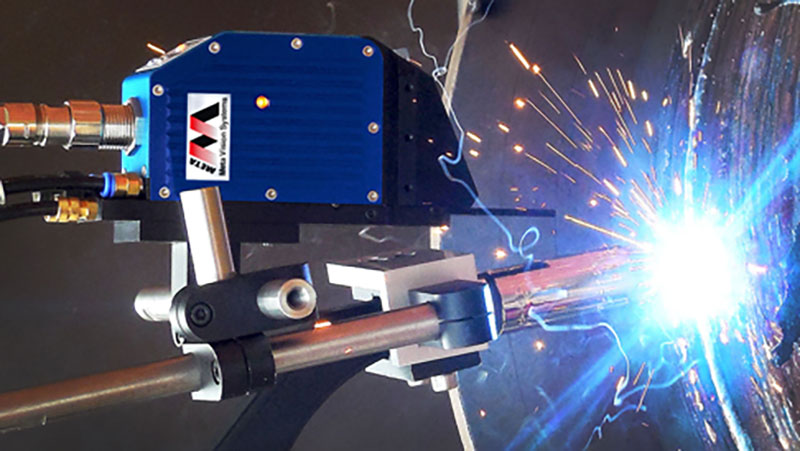

The initial designs were complex and time-consuming to manufacture. The company approached Oxford Brookes for help, and a KTP project was born, with the support of funding from the Technology Strategy Board. The partners recruited Brookes graduate Jonny Biddulph to work in the company, under supervision from James Broughton of the University's Joining Technology Research Centre. James is an expert in materials such as carbon fibre, and joining technology such as sophisticated resins.

By the end of the two-year project, motor production was reduced from seven days to two, material use was reduced, and defect rates were down ten-fold. The cost of a key component was reduced from £95 to under £10, thanks to the introduction of polymers. Lead times that used to stand at eight weeks were heading down to two.

Commercially, the company won a large contract with a major vehicle manufacturer, and made significant inroads into industrial markets. The motors were also adopted for 'the most technologically advanced roadcar ever conceived', the Jaguar C-X75, in which two YASA motors paired with a modest conventional engine to create a car with the performance of a Bugatti Veyron and yet emissions of a Toyota Prius.

Not surprisingly, as Jonny's project came to an end, a job offer was on the table to work directly for YASA as Materials Engineer.