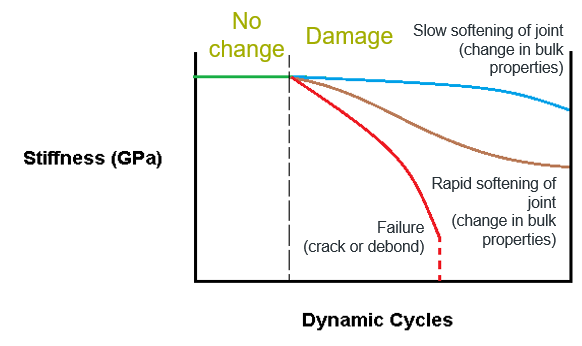

Adhesive bonding is an enabling technology that plays a critical role in light-weighting through the efficient and often only means of joining multi-material components. JTRC has provided novel joining solutions to industry-wide applicable problems that have had a significant impact on national and international sustainability and environmental targets. The outcomes of this impact, listed below, have been influential in the areas of mass production light-weight electric motors, recycling of composites, repair, upgrade and life extension of infrastructure.

Joining Technology Research Centre (JTRC)

Director(s): Professor James Broughton

Contact: jtrc@brookes.ac.uk

About us

The Joining Technology Research Centre at Oxford Brookes is recognised as one of the leading establishments providing industry with access to a unique combination of engineering and scientific skills in the UK today. The foundations of JTRC go back to 1968 and the Centre has since established an international reputation for its interdisciplinary approach to joining problems.

In particular, the research team has undertaken a considerable amount of research and development, and has participated in a wide range of knowledge transfer activities in the use of adhesives and sealants for the aerospace, automotive and construction sectors.

JTRC undertakes consultancy and short- and long-term research contracts in most areas of adhesion, adhesive bonding and sealant technology, and failure analysis. Contact us for a preliminary discussion of your requirements.

Related courses

- Engineering (MPhil / PhD / Masters by Research / PhD by Published Work)

Leadership

Professor James Broughton

Professor & Research Lead in Engineering

/jtrc-01.jpg)

/yasa-ktp.png)