In 2016, the World Health Organisation estimated that more than 4 million people die prematurely each year as a result of being exposed to small particulate matter (PM).

Modern gasoline direct injection (GDI) engines used in road vehicles are a key contributor and particularly harmful, because they produce large numbers of ultra-fine particles that can’t be effectively removed by the tailpipe filters used by most automotive manufacturers. For the GDI engine to remain viable into the future, there was an urgent need to investigate what was causing this, and to develop ways of reducing it.

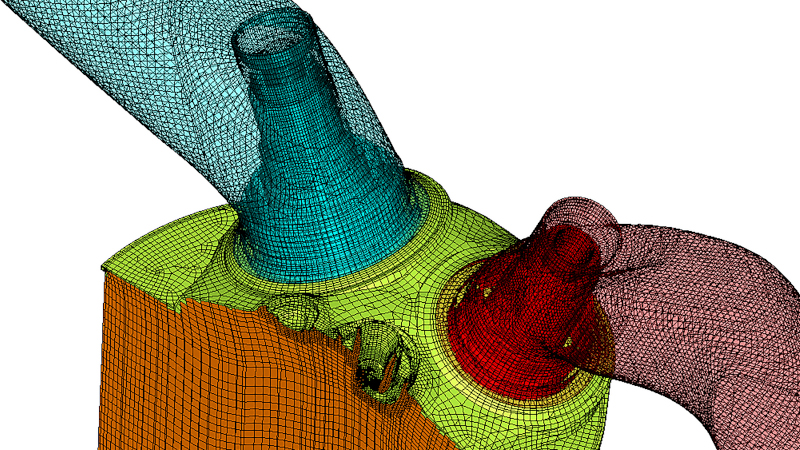

Soot formation in GDI engines is normally associated with imperfect mixing between air and fuel, and with a liquid film of fuel being deposited on piston and cylinder walls during fuel injection. Fabrizio and his team found that a reduction in piston temperature caused liquid fuel to pool in the combustion chamber. When this liquid was burned (‘pool-fire’), it generated vastly increased emissions. Their findings explained why nano-size particles tended to form in large quantities during engine warm-up and transient operation, such as acceleration.

The team’s work revealed for the first time the full extent to which fuel puddling over the piston crown affects soot generation. Armed with this knowledge, engine designers are able to focus on developing new piston technologies and control approaches to ensure temperatures are maintained throughout all stages of vehicle operation that avoid this liquid build-up.

Ford’s technical expert describes the team’s findings as having ‘completely revolutionised’ the manufacturer’s engine design work.