Sustainable wastewater treatment research at Oxford Brookes targets toxic "forever chemicals"

Researchers at Oxford Brookes University have developed groundbreaking new methods of removing dangerous chemicals from wastewater.

Researchers at Oxford Brookes University have developed groundbreaking new methods of removing dangerous chemicals from wastewater.The scientists have developed a hydrodynamic cavitation reactor which uses new ‘bubble technology’ to remove toxic per- and polyfluoroalkyl substances (PFAS) chemicals from wastewater.

PFAS chemicals were invented in the 1930s and used in convenience products like waterproof clothing, nonstick pans, and stain resistant carpets. However, they have more recently been found to be a health hazard that have infiltrated global water supplies. The chemicals are associated with diseases such as ulcerative colitis, thyroid problems, elevated cholestorol, liver damage and cancer.

Removing PFAS chemicals from water sources is a global challenge. In the UK the Royal Society of Chemists has launched a campaign to reduce the levels of PFAS in our water supplies. The EU is planning to restrict the use of PFAS chemicals and in America legally enforceable PFAS levels have been introduced to protect public safety.

Until now, methods of removing PFAS from water have been costly and time consuming, but the new research, led by Dr. Morteza Ghorbani and Professor Iakovos Tzanakis from Oxford Brookes University, identified a potential solution. They carried out the work in collaboration with Sabanci University (Turkey), KTH Royal Institute of Technology (Sweden), and IVL Swedish Environmental Research Institute.

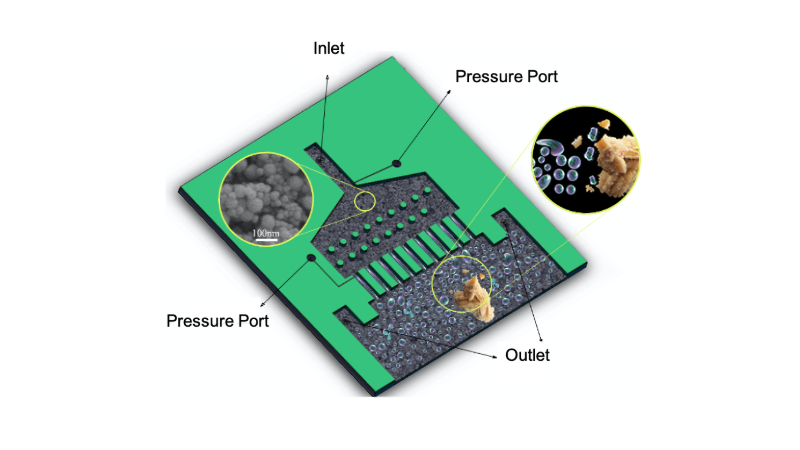

The new technology involves creating bubbles by reducing the pressure of the fluid by passing it through a restrictive area - in this case short channels - within the hydrodynamic cavitation reactor.

Prof Tzanakis said: "This technology has the potential to revolutionize wastewater treatment, making it safer and more sustainable for communities around the globe.

“Traditional methods of removal are often insufficient, costly, or require additional chemicals that can further burden the environment. The advancements in green hydrodynamic cavitation technology provide a promising alternative that enhances the safety and sustainability of wastewater treatment processes.”

The energy-efficient microscale hydrodynamic cavitation reactor was tested at the Hammarby Sjöstad wastewater treatment plant in Sweden.

The research demonstrated that this innovative technology achieves nearly a 36% degradation rate of 11 common PFAS variants in just 30 minutes, without the need for additional chemical additives.

Dr. Ghorbani said: “The results were impressive. We didn’t expect that level of PFAS processing in such a short space of time. We are now exploring the fundamental mechanisms of PFAS removal in depth at Oxford Brookes University to better control and optimize the process.

“Our next step is scaling up our reactor to treat larger volumes of wastewater containing PFAS. Our next step is to treat wastewater containing PFAS volumes up to 20 litres. The reactor for this has already been built. After that our target is to treat volumes up to 200 litres in a wastewater treatment plant in Sweden.

“Our goal is to boost this promising approach by unveiling the intricate physics that drive the technology through the use of a variety of reactors in different countries, thereby ensuring its operational readiness for actual wastewater treatment in the near future.”

This research, which has been published in the Chemical Engineering Journal, has already received an award from the British Council in collaboration with Sabanci University to enable the team to continue their work.

Image: A diagram of the inside of the reactor.